Abrasive Cement Dust No Match for the Smart Elbow® Deflection Elbow

Essroc Materials Inc. produces nearly 400,000 tons of cement annually using two 400-foot rotary kilns. The wet-process cement in Frederick, Md. was continually plagued by dust produced as a natural by-product of cement kilning.

How much dust? Try 120 tons of dust every 24 hours.

A portion of this dust is sold for use in various industrial and agricultural applications, but the majority must be moved pneumatically and recycled back through the kilns through a process call insufflation.

And that’s where the problems really begin.

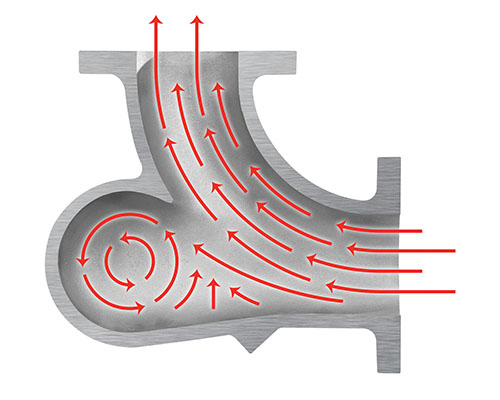

Their pneumatic conveying lines were constantly plugging and surging. Upgrading the system’s pumps and compressors didn’t help — the abrasive dust literally chewed up the long-radius sweep elbows being used. In order to find some respite from the plugging, surging and elbow wear problems, production manager Tom Gibbons replaced the conventional long-radius sweep elbows with 5” cast iron Smart Elbow® deflection elbows.

Plugging and surging have been virtually eliminated, only occurring in very high rates of insufflation (which exceed normal tolerances).

Thanks to the installation of HammerTek Smart Elbow products, maintenance and insufflation system downtime has been dramatically reduced, translating into greater profitability for the company. For the full case study, click here.

To find out how HammerTek Smart Elbows can save your company expensive repairs and downtime while increasing efficiency and productivity, visit us at HammerTek.com.